Capacitor Fluid SAS-60E

Description:

SAS-60E capacitor fluid is recognized as the industry’s highest performing dielectric fluid across all climatic conditions for use in power capacitors and capacitor voltage transformers (CVTs.) Due to SAS-60E’s ability to withstand high stress, capacitor designers can build smaller capacitor units than using capacitor fluids with weaker stress resistance. A saving up to 6.5% on the total manufactured cost of the capacitor unit can be realized. SAS-60E contributes to reliable power transmission and distribution.

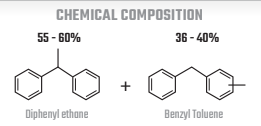

Chemical Composition

Data:

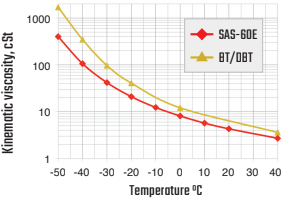

SAS-60E has lower viscosity across all temperature ranges than any other capacitor fluid in the market today. The lower the viscosity, the better hydrogen gas is diffused and absorbed back in the fluid. Capacitor fluid with higher viscosities are prone to exhibit voids due to reduced diffusion and less gas absorption, causing partial discharge just before voltage breakdown. Aslo, SAS-60E’s unique chemical composition does not crystalize like other dielectric fluids. Crystallization impedes the fluids’ ability to diffuse and absorb.

Safety Data Sheet

Crystallization

Viscosity (Log Scale)

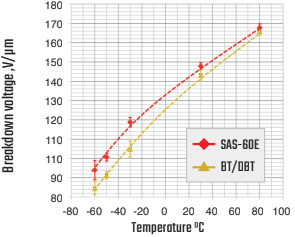

Breakdown Voltage

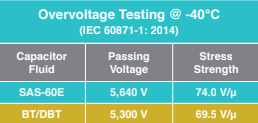

Overvoltage testing(IEC 60871-1: 2014) from an international acclaimed high voltage laboratory accredited to ISO/IEC 17025:2005 by A2LA, proved the SAS-60E has superior breakdown voltage (5,640 V) to that of BT/DBT (5,300 V) when evaluated at IEC’s recommended testing conditions of -40͒ C. These breakdown voltages can be described as stress strength calculated to be 74.0 and 69.5 V/μm respectively. Test report is available upon request.

Applied Benefits:

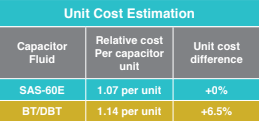

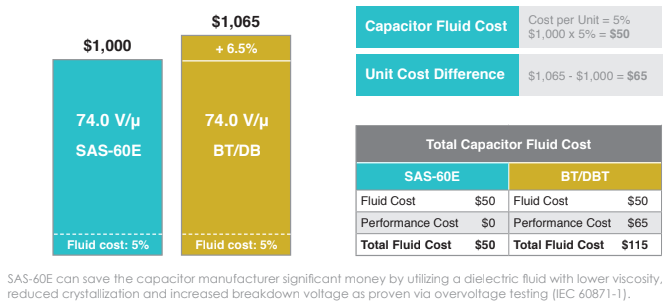

The higher breakdown voltage of SAS-60E allows manufacturers to impose higher design stress to a capacitor. High design stress enables the capacitor manufacturer to utilize thinner layers between electrodes or less series given the same rated voltage, resulting in smaller capacitor units. The small size reduces total unit cost of each capacitor.NCTI’s power capacitor consultants estimated relative total unit cost from the overvoltage test results by using an empirical formula.

Based on the above estimation, a capacitor manufacturer using the BT/DBT fluid would have to build a capacitor unit approximately 6.5% (depending on the design) larger to accommodate the same stress level (74 V/μm) as a manufacturer filling a capacitor with SAS-60E. Below is an illustration depicting the relative cost savings of a $1,000 unit. According to our consultants, fluid cost makes up approximately 5% of the total unit cost of the capacitor. In the calculation below, the price difference between SAS-60E and BT/DBT is negligible because the difference is much smaller than total unit cost.